Examine vehicle design concepts

High-quality design

Convert a designed image to a 3D model

Resolve technical issues to make a drawing

Check the precision on a prototype vehicle

Evaluate performance through simulations and experiments

Perform simulations of pressed portions

Examine the quality of components in a molding die

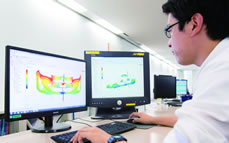

Develop plans for a high-quality,low-cost,worker-friendly manufacturing process

Install jigs and equipment created from 3D data in the manufacturing process

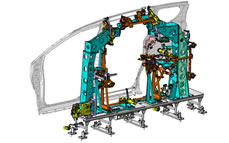

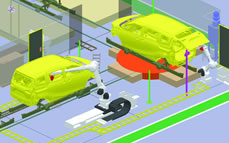

Perform 3D simulations of the manufacturing process to verify productivity and quality

Define conditions for efficient painting through simulations of the movement of painting robots

Conduct examinations to determine component configurations and manufacturing processes that can provide ease of operation by simulating the operations of assembling components

![Our technological capability or [craftsmanship] is highly recognized by expert international institutions](../../images/process/process_text_04_e.jpg)

Make vehicle components of various sizes by stamping steel plates with press machines

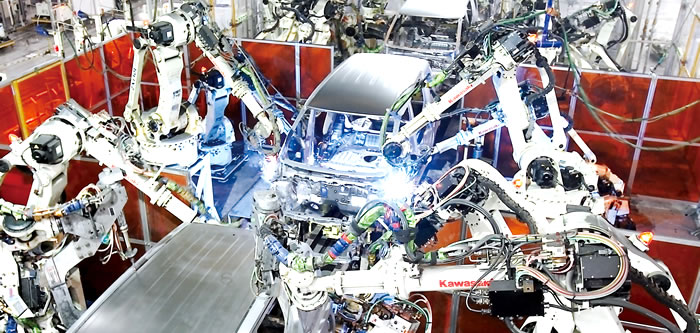

Form a vehicle body by welding pressed components

Provide gloss to the body by painting on multiple layers

Assemble thousands of components including interior trim, meters, electrical wiring, an engine and tires

After strict inspection from multiple viewpoints,such as brakes,lights and exhaust gases,ship the vehicle as a completed vehicle